Mastering the Embroidery Digitizing Process: Your Ultimate Overview

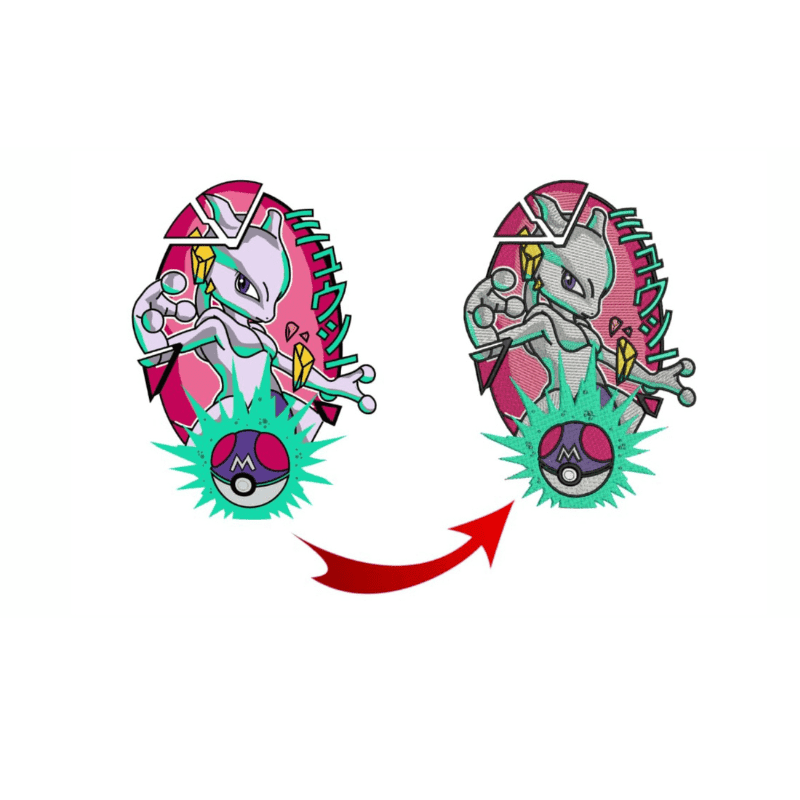

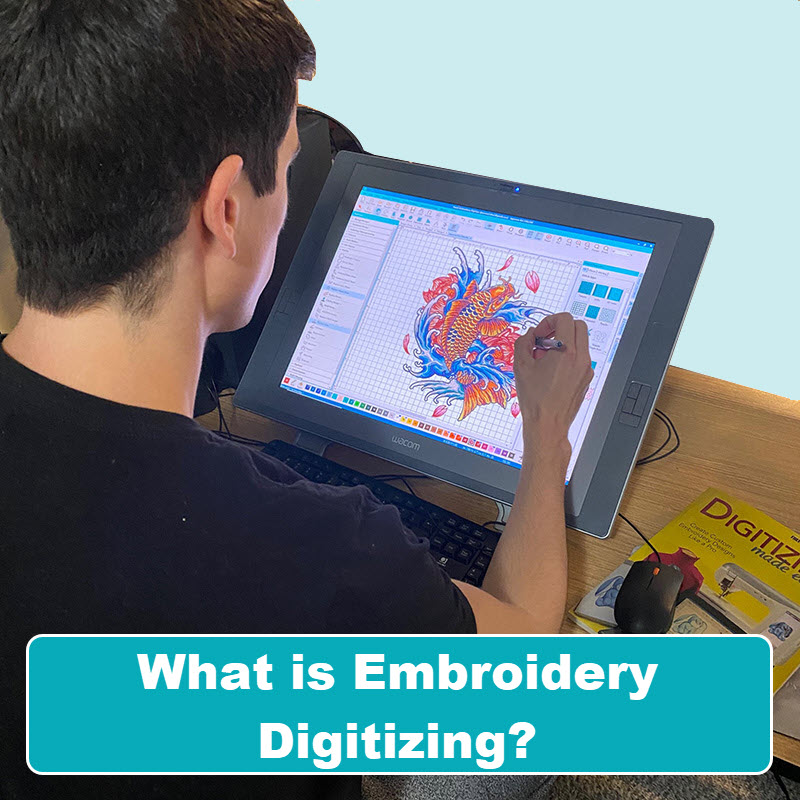

Embroidery digitizing is a precise craft that needs accuracy and knowledge to equate complex styles into digital formats for device embroidery. As artisans embark on this journey to grasp the embroidery digitizing process, an extensive understanding of the basics sets the foundation for quality.

Comprehending Embroidery Digitizing Fundamentals

Needlework digitizing basics develop the structure upon which complex styles are equated into machine-readable styles for accurate stitching. This initial step in the embroidery digitizing process is crucial for ensuring that the final embroidered item is a loyal depiction of the initial style. Comprehending embroidery digitizing basics involves realizing vital principles such as stitch types, stitch direction, thickness, rug, and draw payment.

Stitch kinds play an essential function in figuring out the visual and textural outcome of the stitched style. By selecting the appropriate stitch kind, whether it be satin, fill, or running stitch, digitizers can accomplish the desired result and improve the overall quality of the needlework. Furthermore, stitch instructions influences the flow and measurement of the design, while thickness establishes the spacing and insurance coverage of the stitches.

Moreover, underlay sewing offers stability to the style by securing the textile and stopping distortion during the needlework process. Draw compensation is an additional vital factor to consider to combat the natural tendency of textile to contract when sewn. Grasping these needlework digitizing basics is essential for producing professional-quality embroidered items.

Choosing the Right Digitizing Software Application

Picking the appropriate digitizing software is an essential choice that substantially influences the effectiveness and high quality of the embroidery digitizing procedure. Digitizing for Embroidery. When choosing the right digitizing software application, it is important to take into consideration factors such as the complexity of layouts you plan to develop, the user-friendliness of the software application, the degree of customer assistance supplied, and the compatibility with your needlework maker

There are various digitizing software program choices available out there, varying from fundamental programs for novices to advanced software application for expert digitizers. Some preferred choices consist of Wilcom EmbroideryStudio, Hatch Needlework Software, and PulseID. These software application bundles provide a large variety of tools and features to help you create intricate designs effortlessly.

Prior to deciding, it is suggested to discover the various software application options through free tests or demonstrations to figure out which one best fits your needs. Additionally, reviewing testimonials and seeking recommendations from seasoned digitizers can supply important insights right into the staminas and weaknesses of each software (Digitizing for Embroidery). By thoroughly evaluating your needs and contrasting the functions of different digitizing software program, you can make an educated choice that boosts your embroidery digitizing workflow

Digitizing Devices and Techniques

Optimizing Style Settings for Embroidery

Understanding the complexities of layout settings is fundamental in attaining optimal results in the needlework digitizing process, structure upon the structure laid by understanding digitizing devices and techniques. When enhancing layout settings for embroidery, it is essential to think about variables such as stitch type, density, padding, pull payment, and enrollment. Enrollment settings line up various elements of the style properly, maintaining general Full Article layout integrity.

Troubleshooting Common Digitizing Issues

When coming across usual digitizing issues throughout the embroidery process, it this hyperlink is necessary to comprehend the source and carry out effective options without delay. One common issue is stitch thickness issues, where stitches may be also dense, triggering the textile to tighten, or as well thin, leading to spaces in the layout. Readjusting the stitch density settings in the digitizing software application can aid fix this problem.

One more constant challenge is thread breaks during the needlework procedure. This can take place due to different factors such as wrong stress setups, dull needles, or using low-quality thread. Making sure appropriate upkeep of the needlework equipment, including regular needle changes and tension modifications, can lessen the incident of string breaks.

Moreover, layout enrollment mistakes can cause misaligned components within the needlework layout. Examining the layout placement in the digitizing software program and making essential changes prior to sewing can assist in preventing this problem. By dealing with these usual digitizing problems immediately and successfully, you can make sure a smoother embroidery process and next premium completed products.

Conclusion

Finally, understanding the needlework digitizing process requires a strong understanding of the essentials, the ideal choice of software, and expertise of tools and techniques. Maximizing style settings and troubleshooting usual digitizing problems are important action in making sure premium embroidery outcomes. By complying with these steps faithfully, one can accomplish precision and performance in the digitizing process.